Mobile Wet Mix Plant

Price 2200000 INR/ Piece

Mobile Wet Mix Plant Specification

- Air Pressure

- 6-8 kgf/cm2

- Tank Dimensions (Mm X Mm X Mm)

- Water Tank: 2500 1500 1500 mm

- Temperature

- Ambient (Cold Mix Operation) Celsius (oC)

- Compressor Type

- Rotary Vane / Screw Type (Optional for Pneumatic Controls)

- Coverage Area

- 400 600 m /hour Square Meter (m2)

- Mount Type

- Mobile Chassis with Tyres & Drawbar

- Hopper Capacity

- 4 Bins 5 m each (aggregate feeder) Cubic Meter (m3)

- Working Width

- 2.5 m 3.0 m

- Driven Type

- Electric Motor / Diesel Engine

- Noise Level

- <85 db

- Tank Material

- Mild Steel (MS) with Anti-Corrosion Coating

- Fuel Type

- Diesel (for water pump & auxiliary engine)

- Hole Size

- Standard Graded Aggregate Bins Meter (m)

- Type

- Concrete Grinder

- Material

- Mild Steel (MS) Heavy-Duty Structure

- Capacity

- 60-300 TPH Ton

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling System

- Human Machine Interface

- Vibration Frequency

- 50 Hertz (HZ)

- Drum Diameter

- NA Meter (m)

- RotorDiameter

- NA Meter (m)

- Power

- 60-120 Horsepower (HP)

- Size

- Compact & Mobile Single Chassis Mount

- Color

- Grey

- Weight

- 15000-25000 Kilograms (kg)

- Dimension (L*W*H)

- 12 m 2.5 m 3.5 m Meter (m)

- Warranty

- YES

Mobile Wet Mix Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Mundra/Nhava Sheva/Kandala

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 15 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Export-worthy packaging with proper protective covering Major components packed with waterproof wrapping & anti-rust coating Control panel, electrical parts & sensitive units packed in wooden crates Heavy components secured on trailers/trucks or in 40 ft HQ containers (for overseas shipping) Ensures safe handling during long-distance transport & loading/unloading

- Main Export Market(s)

- Asia, Eastern Europe, Australia, Central America, North America, South America, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015 Certified Quality Management System CE Certification (for export models, if applicable) MSME / Udyam Registration (India) GST Registered Manufacturer Trademark Registered Himalaya Engineering Company In-house Quality Assurance & Testing Certification

About Mobile Wet Mix Plant

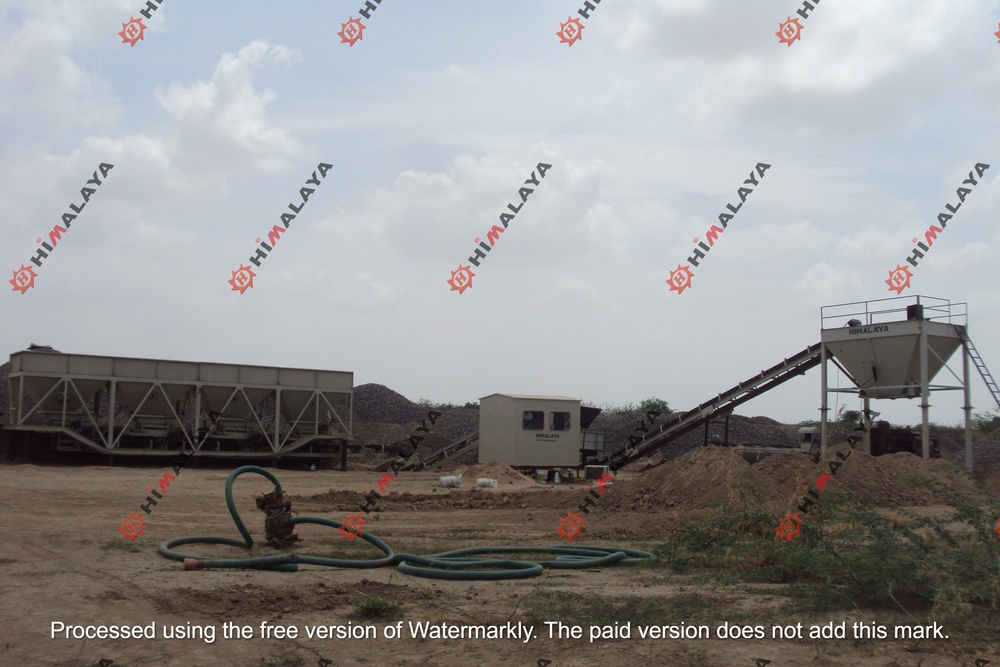

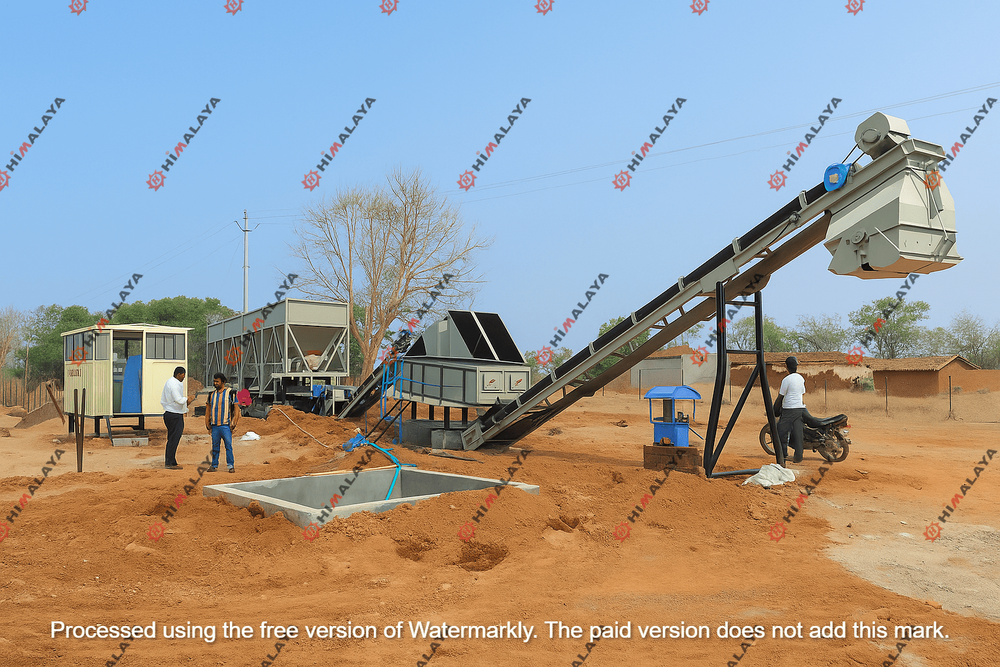

Himalaya Engineering Company offers a high-performance Mobile Wet Mix Macadam (WMM) Plant designed for quick setup, easy transportation, and reliable operation. This plant is ideal for producing homogeneous wet mix macadam used in road base and sub-base layers. Mounted on a sturdy, mobile chassis, it ensures excellent flexibility for contractors working on remote or multiple project sites.

The plant combines precision engineering with advanced control systems to deliver consistent output and superior mix quality. All components, including the aggregate feeder, pug mill mixer, water tank, and control cabin, are efficiently integrated for smooth and continuous operation.

Key Features:

-

Fully mobile design for easy transportation and fast installation.

-

High-capacity pug mill mixer for uniform mixing and superior material strength.

-

Accurate aggregate and water feeding system for consistent mix quality.

-

Heavy-duty chassis ensures durability and stability during operation.

-

User-friendly control panel for efficient operation and monitoring.

-

Available in various capacities ranging from 60 TPH to 300 TPH.

-

Low maintenance and fuel-efficient design.

High Efficiency and Large Coverage

This plant delivers a wide coverage area, efficiently handling 400-600 square meters per hour, and has a modular capacity ranging from 60 to 300 tons per hour. Its heavy-duty structure and computerized controls ensure continuous production and consistent results, making it suitable for medium to large-scale infrastructure projects.

Mobility and User-Friendly Design

Designed for rapid relocation, the Mobile Wet Mix Plant comes mounted on a single chassis with durable tyres and a drawbar. Compact and rugged, it simplifies setup and dismantling, reducing downtime between projects. Its automated and computerized systems make it easy for operators to monitor and adjust mix parameters as needed.

Advanced Mixer Technology and Durability

Using mild steel construction with anti-corrosion treatment, this plant is built for longevity in demanding environments. The human-machine interface (HMI) ensures safe, precise control, while the robust electric or diesel drive systems and automatic pneumatic controls (optional rotary vane or screw compressor) deliver reliable performance.

FAQ's of Mobile Wet Mix Plant:

Q: How does the Mobile Wet Mix Plant improve construction efficiency?

A: The plant automates material feeding, mixing, and discharge, significantly reducing manual labor and expediting site preparation. Its large hourly coverage and capacity ensure faster project completion and consistent mix quality.Q: What types of projects is this mobile wet mix plant suitable for?

A: It's designed for road construction, airport runways, and large paving jobs that require on-site production of wet mix. The plant's portability allows for quick setup at various locations, making it ideal for infrastructure projects requiring mobility.Q: When should I use the optional rotary vane or screw-type compressor?

A: These compressors are recommended when pneumatic controls are required for aggregate and powder handling or automation upgrades, offering enhanced precision and operational convenience.Q: Where can the Mobile Wet Mix Plant be deployed?

A: The plant is intended for outdoor construction sites across India, adaptable to urban and remote environments thanks to its mobile chassis, durable construction, and flexibility in power source selection.Q: What is the process for setting up and operating the plant?

A: Position the plant using the chassis and tires, connect to a suitable power source or diesel engine, fill the aggregate bins and water tank, and start the automated control system. The computerized interface allows real-time monitoring and adjustment.Q: What are the benefits of the anti-corrosion coated mild steel structure?

A: This coating enhances the plant's resistance to harsh weather and aggressive construction site conditions, ensuring a longer lifespan and reduced maintenance costs.Q: How does the Human Machine Interface (HMI) contribute to plant safety and performance?

A: The HMI provides intuitive controls and safety alarms, streamlining plant monitoring, improving operator visibility, and quickly detecting any issues to minimize downtime and maintain quality standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wetmix Macadam Plants Category

Wet Mix Plant

Price 2300000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1800028000 Kilograms (kg)

Compressor Type : Rotary Vane or Screw Type (optional for pneumatic controls)

Coverage Area : 400 600 m /hour (depending on capacity) Square Meter (m2)

RotorDiameter : NA Meter (m)

Industrial Wetmix Macadam Plant

Price 2300000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1000080000 (depend on cpapacity) Kilograms (kg)

Compressor Type : Electric Screw or Piston Compressor

Coverage Area : 40120 Square Meter (m2)

RotorDiameter : 0.81.2 Meter (m)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS